Mechanical engineers in the Meza Research Group at the University of Washington draw inspiration from natural structures to develop new materials.

Q&A: A UW materials lab probes the mysteries of toughness at the nanoscale

Mechanical engineers in the Meza Research Group at the University of Washington draw inspiration from natural structures to develop new materials.

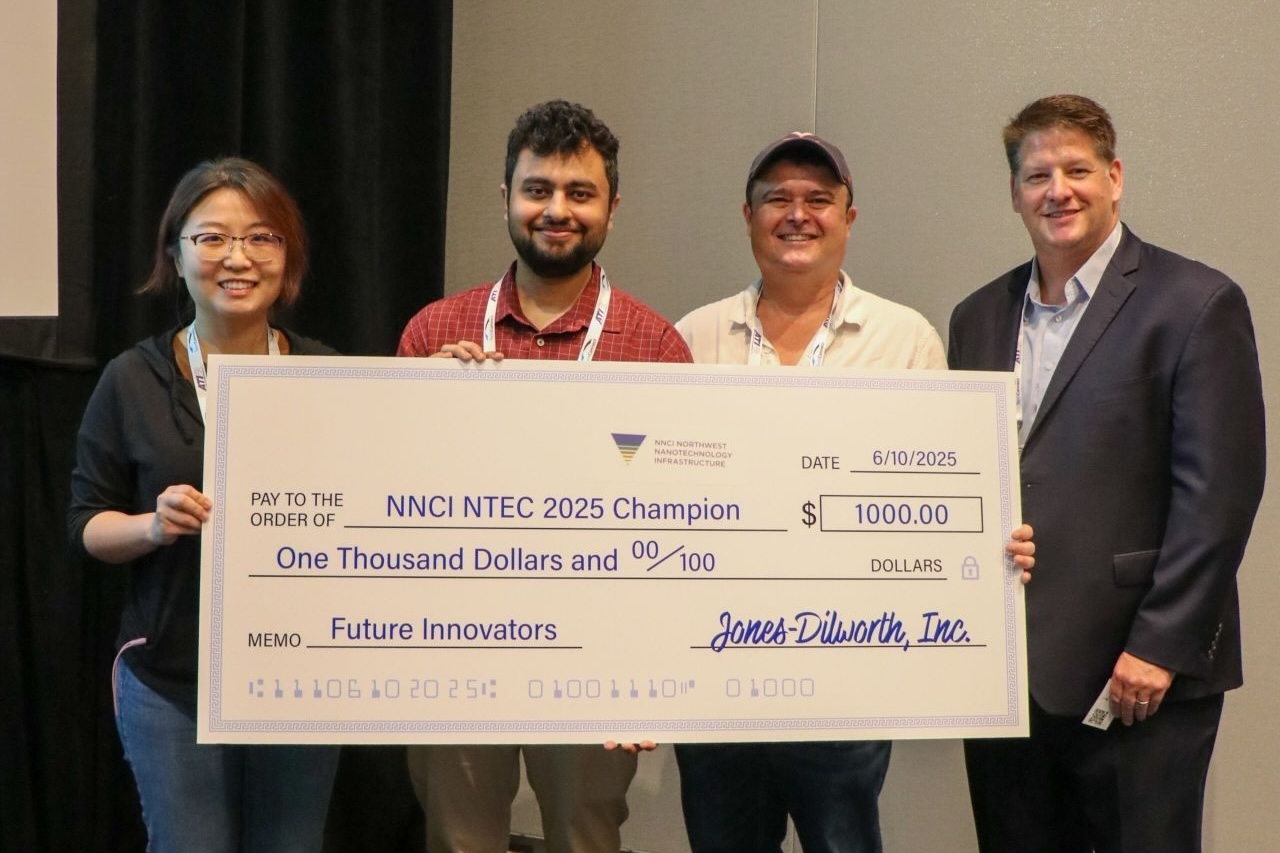

On June 10, 2025, Anmol Purohit, Dr. Ji Feng, and Almond Lau won first prize at the NNCI NTEC Showcase for their project, “Synthesis of metal-organic framework particles for removal of short and ultra-short chain PFAS from water”.

NanoES faculty member Ayokunle Olanrewaju (bioengineering, mechanical engineering) and collaborators Ashleigh Theberge and Erwin Berthier will develop a platform for at-home self-collection of blood, serum separation, and sample stabilization at sufficient sample volumes for comprehensive HIV monitoring.

David Cobden (physics), David Ginger (chemistry), Charles Marcus (materials science & engineering, physics), and Xiaodong Xu (physics, materials science & engineering) have been recognized for significant influence in their chosen field or fields of research through the publication of multiple papers in the top 1% of citations over the last decade.

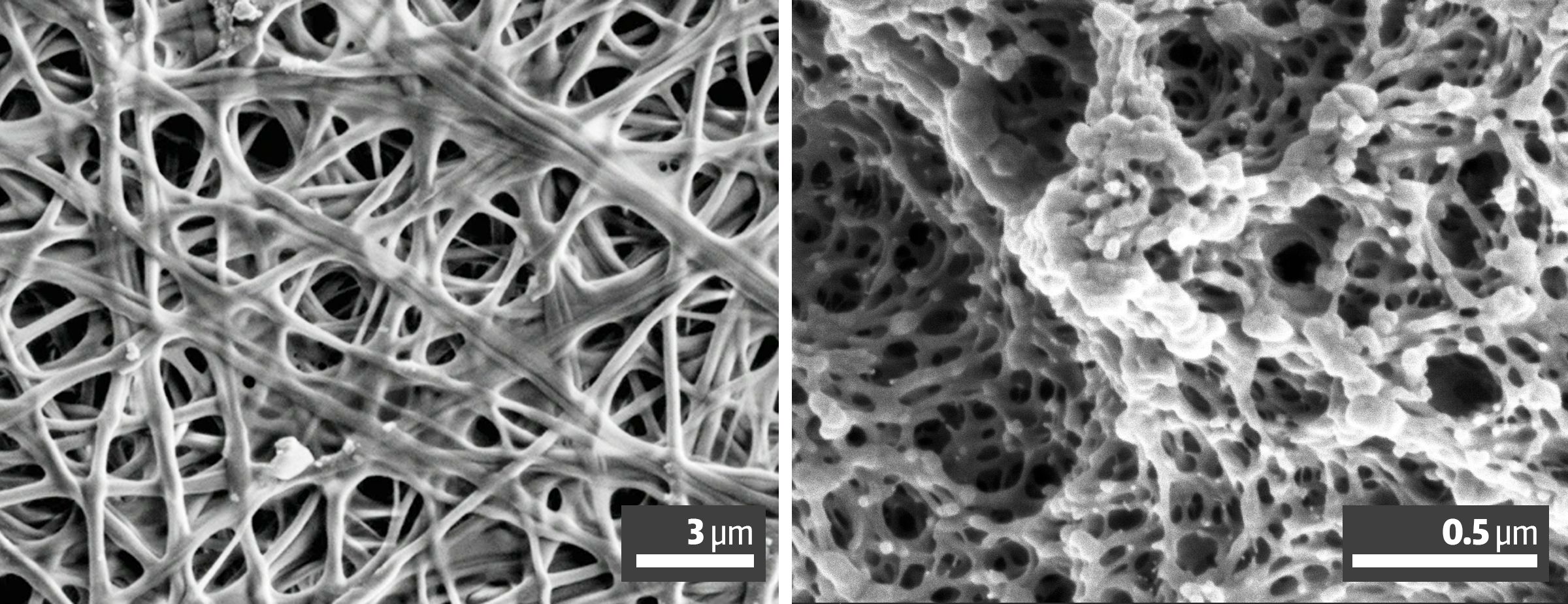

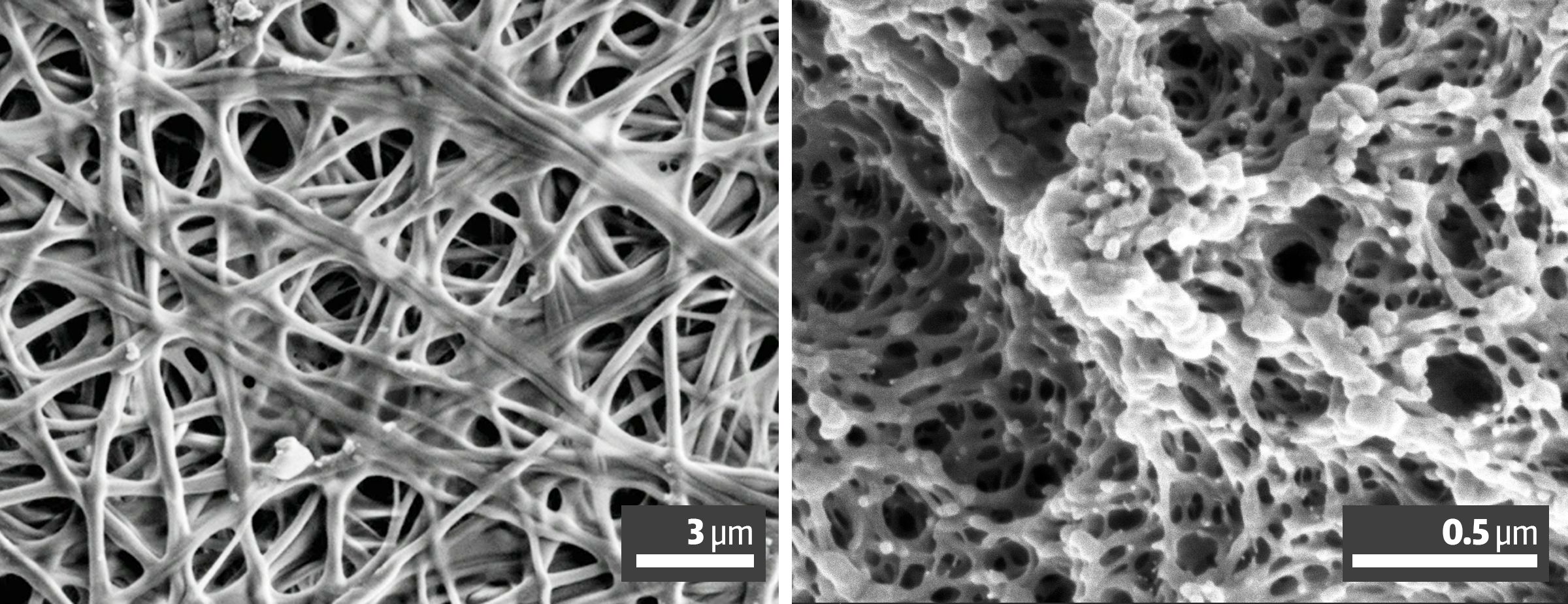

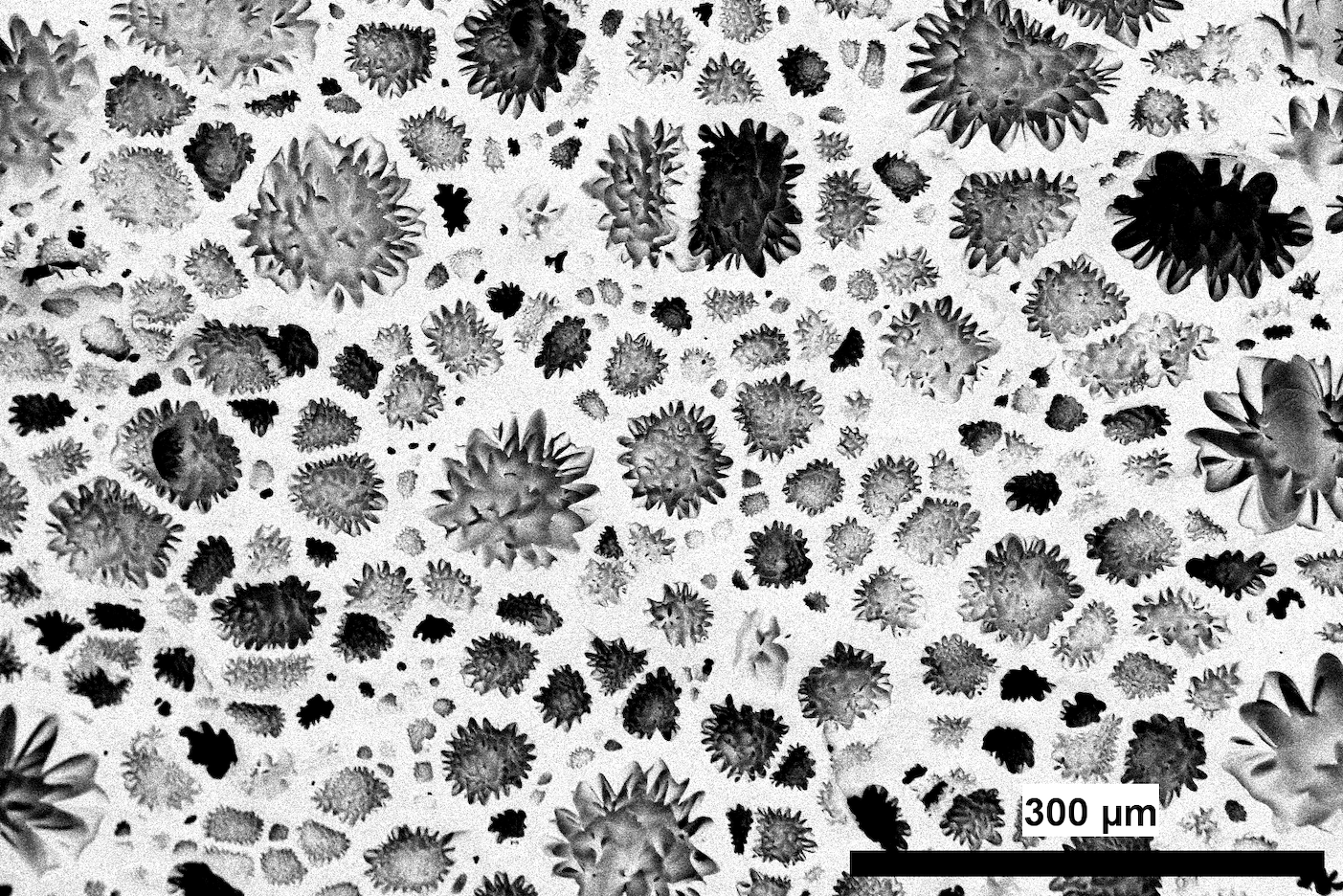

Santhosh Sridhar, Ankush Nandi, and Shaunak Deshpande won first prize for “Foam in Bloom” in the “Most Stunning” category in the 2025 Plenty of Beauty at the Bottom image contest hosted by the National Nanotechnology Coordinated Infrastructure (NNCI).

Researchers in Mo Malakooti’s lab (mechanical engineering) have created a recyclable, flexible and self-healing composite material that could replace traditional circuit boards in future generations of wearable electronics.

NanoES faculty member Ayokunle Olanrewaju (bioengineering and mechanical engineering) has earned a Maximizing Investigators’ Research Award from the National Institutes of Health’s National Institute of General Medical Sciences. The $2.1 million grant is for five years. Often referred to as “R35 awards,” these grants support broad research programs over the course of several years, providing the nation’s most talented and promising researchers “greater stability…enhancing scientific productivity and the chances for important breakthroughs.”

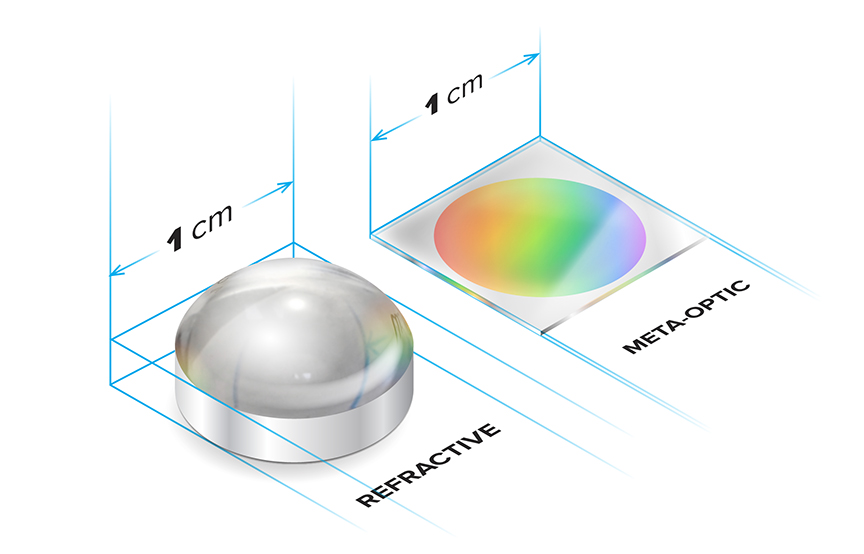

In a first-of-its-kind achievement, a team of researchers at the University of Washington and Princeton University, co-led by NanoES faculty member Arka Majumdar (electrical & computer engineering, physics) and including NanoES director Karl Böhringer (ECE, bioengineering), has shown that a camera containing a large aperture, ultra-flat optic can record high-quality color images and video comparable to what can be captured with a conventional camera lens. The metalens, developed at the Washington Nanofabrication Facility (WNF), is hundreds of times smaller and thinner than a conventional camera lens, offering substantial savings in volume, weight, and device battery life.

NanoES faculty member Mohammad Malakooti (mechanical engineering) has received the prestigious National Science Foundation (NSF) Faculty Early Career Development (CAREER) Award to advance sustainable manufacturing of flexible electronics.

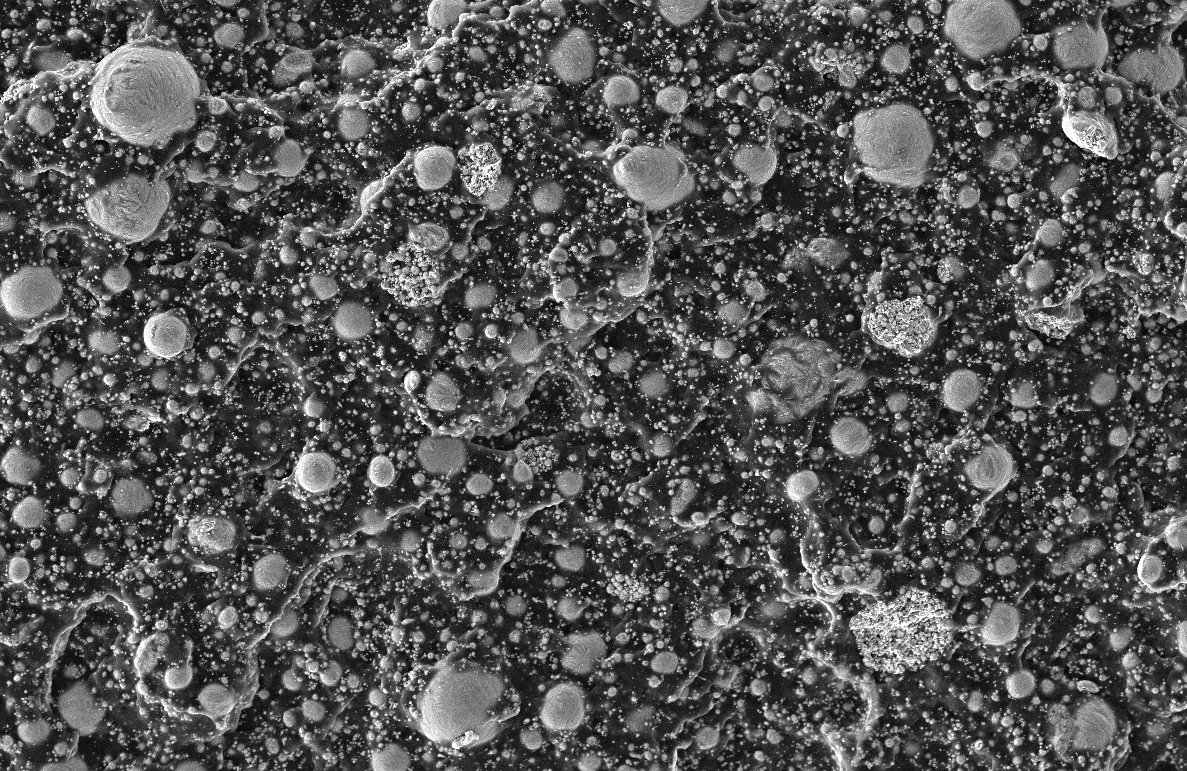

Researchers in the Miqin Zhang lab (materials science & engineering) have developed a promising new way to deliver messenger ribonucleic acid (mRNA) to cancer cells. Their novel polymer platform, a new nanoparticle comprised of perfluoroheptanoic acid (PFHA), polyethyleneimine (PEI), heparin (HP) and mRNA, shows enormous potential to outperform the current standard platform, lipid nanoparticles (LNPs).