Tunoptix, an optics startup co-founded by University of Washington (UW) electrical and computer engineering professors Karl Böhringer and Arka Majumdar, was awarded $223,000 in Small Business Technology Transfer (STTR) funding from the Defense Advanced Research Projects Agency (DARPA) to develop metasurface lenses (or metalenses) for imaging in satellites at the UW Washington Nanofabrication Facility (WNF). The STTR program supports the commercialization of basic science innovations by providing federal funds to cooperative research and development (R&D) initiatives between small businesses and research institutions. The WNF offers open access to nanofabrication equipment and processing expertise for basic and applied research, advanced R&D, prototype manufacturing and low-volume production.

Miniaturization of today’s glass-based lenses is hindered by the limitations of traditional glass-cutting techniques and the use of multiple lenses to properly focus light, increasing the overall thickness and weight of the lens. Tunoptix develops metalenses – flat surfaces that focus light through a specially designed array of nanostructures – as a much smaller, lighter alternative to conventional lenses. These thin, compact lenses have the potential to transform everything from microscopy to cameras, sensors and displays.

Currently, most metalenses are microscopic in size. While this works for some applications, larger lenses are needed to capture enough light to generate high quality images under low light conditions. DARPA is particularly interested in the development of light-weight lenses, up to a meter in diameter, that can be used in imaging systems onboard orbiting satellites.

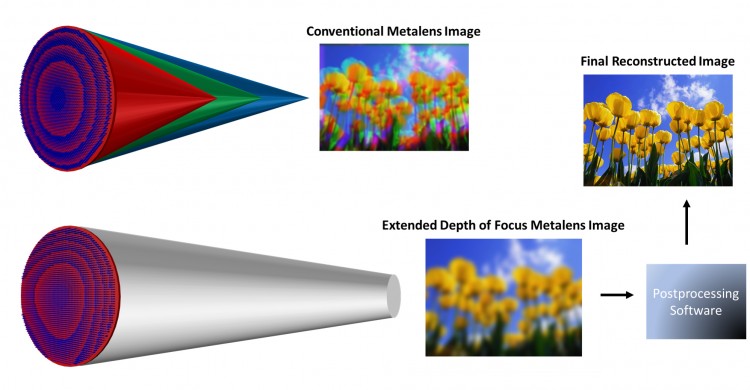

Making metalenses at such a large scale is challenging. Generally, metalenses produce accurate images only within a narrow color range, outside of which the image appears blurry or distorted. Several techniques have been developed to enable small metalenses to generate clear images across the visual spectrum, but they are not scalable. In addition, because metalenses are composed of sub-wavelength structures, the fabrication of a large area metalens is slow and more likely to have imperfections.

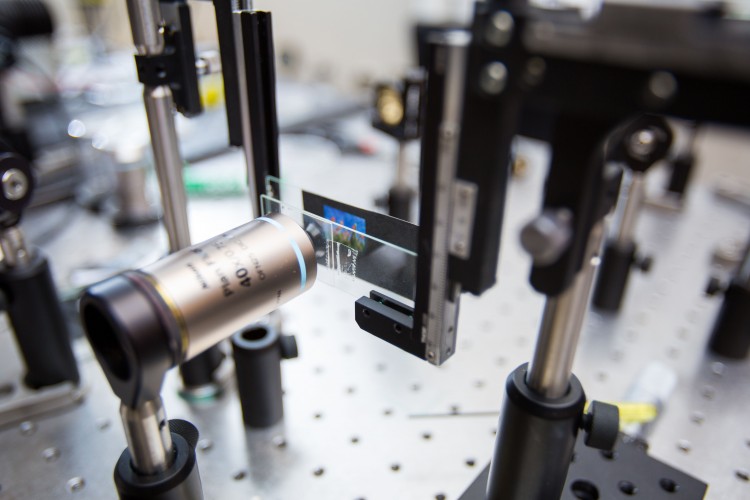

To create large-scale, light-weight lenses capable of yielding high quality images, Tunoptix combines its uniquely designed metasurfaces with computational post-processing. This approach can yield full-color images and mitigate the inevitable fabrication imperfections in metasurfaces. Importantly, it can be scaled to larger metalens designs. Tunoptix’s STTR-funded R&D will focus on optimizing its metasurface designs and computational algorithms. During Phase I of this STTR, Tunoptix will begin fabricating a centimeter-scale metalens, while also developing designs for a metalens of at least 10 centimeters. Tunoptix fabricates its metalenses at the WNF using conventional computer chip manufacturing processes including lithography, etching, and deposition.

“We can design endless variations of metalenses in the lab, but ultimately, we need to create physical prototypes of our designs to prove that they work,” said Majumdar. “The WNF has been essential to developing this technology and winning this STTR. Ultimately, the WNF allows us to innovate faster – we can rapidly test our ideas to create better metalenses while ensuring our intellectual property is protected, enabling us to commercialize our research.”

“We are thrilled to have Tunoptix using the WNF to develop their metalens technology,” said WNF director Maria Huffman. “We see our role in the innovation ecosystem as helping move new ideas out of the research lab and into the marketplace by providing small entrepreneurial companies like Tunoptix access to equipment and processing technologies that they are not in a position to purchase or maintain themselves.”

Tunoptix was founded in 2017 with funding from the venture capital firm IP Group. With the support of IP Group and the UW’s innovation incubator CoMotion, Tunoptix leveraged research from Majumdar and Böhringer’s labs to integrate metalenses with microelectromechanical (MEMS) devices, creating a small, tunable lens with autofocus and zoom capabilities. Tunoptix is now also developing metasurfaces coupled with computational processing to enable cameras to image objects at various distances without needing to refocus or switch out lenses.

While exploring applications of interest to DARPA, Tunoptix will also pursue the use of its metalenses in displays for machine vision. In the future, Tunoptix’s metalens technology may eventually be applied to augmented and virtual reality displays and medical devices like endoscopes. Upon successful completion of STTR Phase I R&D, Tunoptix will become eligible for Phase II funding.